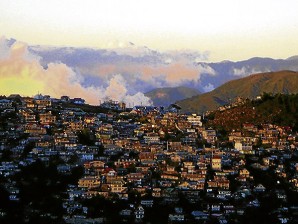

BEHIND THE FOG The fog has lifted. Behold, the landscape of houses hugging this mountainside in Baguio City looks like a Manny Baldemor painting as the air turns nippy with the advent of the “Ber” months. With its “brrr” clime, the country’s summer capital is an attraction for all seasons. EV ESPIRITU/INQUIRER NORTHERN LUZON

Each morning before they begin work, young workers of a Church-based factory in Baguio City known for its strawberry and “ube” jams pray and embark on an hour of “tai chi” and “shibashi,” both slow and meditative exercises.

“The prayer helps give me inner strength and tai chi and shibashi help awaken my nerves to help me better focus and be efficient in my work,” says Jackie Rose Lubbong.

Lubbong, 19, from Aguinaldo, Ifugao, is one of the workers of the Mountain Maid Training and Development Foundation. Through its homegrown factory, the foundation run by the Religious of the Good Shepherd, has been sending young people, mostly from the Cordillera, to college since 1952.

Now in her third year taking up business administration, Lubbong learned that big companies, such as Toyota, give importance to meditation and fitness to improve their workers’ efficiency.

Lubbong is one of the more than 200 students enrolled as part-time workers at the foundation. She spends three days at the workplace and three days in school each week.

Sr. Guadalupe Bautista, who coordinates the foundation, says “holistic health” and “value formation” are among the secrets of Mountain Maid. “This is why the prayer and exercise sessions are included as part of the work hours of our workers,” she says.

Quality standards

Maintaining and sustaining quality standards is also one of the secrets of the foundation. Bautista says the products regularly go through strict inspections of the Food and Drug Administration, the Department of Health and the Department of Science and Technology.

Inspections include regular laboratory tests for traces of aflatoxin, a toxin produced by mold that can damage the liver and may lead to liver cancer. The fungi that produce aflatoxin grow on crops such as peanuts, wheat, corn, beans and rice.

To prevent aflatoxin infestation, the foundation has invested in a facility called dehumidifier, which regulates humidity inside the workplace, says Bautista.

Benefits

Professionalization is another secret. This includes giving workers fair wages, benefits such as 13th month pay, and bonuses as required by the labor department. All workers are members of the Social Security System and beneficiaries of the Philippine Health Insurance Corp.

“We are actually giving our workers more than what the law provides,” says Bautista.

Other benefits include free snacks and a subsidized lunch for workers. “Where did you see a P5 lunch with unlimited rice?” asks Bautista, as she shows workers queuing up for their lunch break.

She says that if workers are satisfied with their pay, they become efficient.

Part of the professionalization program is letting workers attend health and sanitation seminars, such as HIV and AIDS concerns, which are extended by government and private agencies. “All seminars and trainings are credited as work hours of the employees,” says Bautista.

Discipline of saving

Not used to handling cash, many young workers would tend to spend their hard-earned money on less important or unnecessary items such as high-end mobile phones and other gadgets.

So the Good Shepherd sisters taught them about the discipline of saving. They have devised a scheme where the workers are forced to save.

Through the scheme, the workers are advised to maintain two accounts—one for expenses such as food, house rent and transportation and another for tuition and other fees, and for contingencies.

“I was taught to appreciate the value of money. I came to learn how to really budget and spend only on necessities,” says Christopher Rivera, 20, who is taking up accounting technology, his second course after finishing financial management.

The scheme has been adopted by some mothers and out-of-school youth who also work with the foundation.

Mechanization

To meet the demands of a growing clientele, Mountain Maid has gradually mechanized over the years.

Grinding peanut into brittle used to be done with a rolling pin. But in 2008, the foundation bought a grinder.

In 2004, Mountain Maid began to mechanize production. For example, making ube jams and mixing flour for baked products have been aided by machines.

Currently being installed at the Good Shepherd compound in Baguio is a diesel-fueled facility for a cheaper but efficient way to process ube jams. The only product that is still done manually is strawberry jam.

The industry that the Good Shepherd sisters initiated is also benefiting strawberry and ube farmers.

The foundation has 31 organized strawberry and ube farmers who are assured of a fair price and sure market for their products through a contract-growing scheme, says Bautista.

When strawberries become expensive, contract growers are allowed to sell their produce at the market. During the rest of the season when prices fluctuate, strawberry farmers prefer the fair price of the foundation, she says.

Overall, the secrets of Mountain Maid’s success are actually open, says Bautista. “These include discipline in production, cleanliness, orderliness, good manufacturing practices, commitment, dedication, perseverance, team work, innovation, sharing blessings and value formation.” she says.

“Above all, prayer and dependence on God’s abiding providence.”